Oilybits, OB Series, Centrifugal Oil Cleaners

Oilybits OB Series Oil Centrifuge removes water and all heavier-than-oil particle contamination from oils. Designed for use with Diesel, Bio Diesel, Vegetable Oil, Gear Oil, and Lubricating Oil, the centrifuges will work more efficiently if the oil is heated prior to introduction to reduce viscosity to approximately that of water.

This centrifuge requires a suitable high pressure pump to feed it with oil, it uses some of this as a wet seal around its central shaft to prevent wear, and the rotor is propelled at up to 9100 RPM by the oil as it passes through jets of below 1mm diameter (varies between models), creating centrifugal forces of up to 3634 times gravity. At this point all heavier-than-oil particles are forced to the outside wall of the rotor, where they mass into a semi solid layer, cleaner oil then flows outward into your storage vessel. Multiple passes may be required to gain the highest purity, as the centrifuge passes some dirty oil throughout its operation (the oil that seals around the shaft). This centrifuge is designed for continuous cleaning of motor oil in an engine, so it is circulating a relatively small amount of oil which is very hot (and therefore thin), and has been filtered to 10 microns with the vehicles oil filter, it polishes this over and over. You cannot put very dirty oil through this centrifuge or it will block the pump, block the jets, or fill the rotor with water/debris too soon, the oil going in needs to be quite clean to start with, strained to at least 100 microns through a nylon bag or similar with all free water drained off. An alternative centrifuge which can clean oil in a single pass, tolerate particles up to around 5mm, and self-drain water, is the RPC-103, our most popular model. Other similar machines can be found here: Motor Driven Centrifuges

By increasing G-Force, you are doubling the relative weight of an object by 100% per 1G, at 0G an object weighs true upon the surface of the earth, at 1 G an object weighs twice its true weight, so, for example at 4000 G, a particle of dirt which might weight 0.1 gram will weigh 400 grams, and because of this, it will settle through a body of liquid much faster than it would if it were its original weight

The centrifuge will require emptying of contaminants periodically, although regularity will depend upon how contaminated your oil is, the better you strain your oil beforehand, the longer the centrifuge will operate before cleaning is required

For cleaning of lubrication oil that has been used in a combustion engine, please note that whilst the centrifuge will remove all heavier-than-oil particles, it will not reverse changes that have occurred to the oil at a molecular level - for example the black colour of used engine oil is not only caused by carbon deposits such as soot (which will be removed) but by a change in the molecular structure of the oil caused by the combustion of hydrocarbons within it, this produces black liquids such as asphaltine, and this colouring cannot be removed by using a centrifuge or any other means of fitration

OILYBITS RECOMMEND MODELS

OB-020 - For small batch cleaning in confined areas, such as in a vehicle

OB-025 - For small batch cleaning in the workshop, or in a vehicle with adequate room

OB-030 - For small batch cleaning in the workshop, or in a vehicle with adequate room

OB-050 - For medium batch cleaning in the workshop

OB-100 - For large batch cleaning in the workshop

OB-200, OB-400 & OB-600 - For very large batch cleaning in the workshop, or for very high contaminant level removal, for example metal silt from machinery

Alternatively the centrifuges can be used for what they were designed - removing particle contamination from engine oils in ships, trucks, and machinery.

Pictured Below, OB-020, OB-025, and OB-050

Pictured Below, OB-200

Pictured Below: OB-600 (Shown without clamp, though a clamp is included)

MOUNTING BRACKETS

OB-020, OB-025, and OB-050 centrifuges are supplied complete with a mounting bracket for ease of mounting (shown in main image at top) Brackets are not available for any of the larger models after OB-050, they are just supplied with 4x bolt holes for mounting to a flat surface with centre hole for drainage. The lack of brackets on the larger models is simply because the brackets are made in the UK and we dont sell high enough volumes of the larger models to warrant making brackets for them, but of course we can have one-offs made if you would like us to get a quotation

PLEASE NOTE - WE CAN ALSO SUPPLY WITHOUT BRACKET IF A BRACKET IS NOT REQUIRED.

CENTRIFUGE SIZE VS. SPEED & G-FORCE

If you look at the RPM figures based on oil pressure in the chart below, you will notice that the bigger the Centrifuge, the less RPM the rotor moves at. This reduction in RPM is caused by the increasing weight, surface area (drag) at the maximum permissible pressures for safety the rotors will only spin at the RPM stated. The reduction in RPM results in lower G-Forces inside the rotor (at the same radius from the center) and therefore contamination will not seperate as fast in some of the larger models as it does in the smaller ones. It would make huge sense therefore to have multiple smaller units rather than one big Centrifuge. Consulting the chart below you will see that OB-050 has the greatest G Force of all models, and OB-100 the least

WHAT TO EXPECT FROM AN OB SERIES CENTRIFUGE & GENERAL GUIDANCE

Due to a large number of enquiries following supply, we have enhanced the information and manuals provided with the equipment, and summarise what to expect (in average workshop conditions) from a Centrifugal Oil Cleaner below;

Purpose - An OB Series Centrifuge is a progressive fuel-polishing device, it is not intended to purify foul oil in one pass, moreso to gradually remove contaminants from oil that cannot be removed by the lowest rating of washable filter (this being 80 micron), and particles that are too small to be removed by any filter (smaller than 1 micron), by combining Washable Filters Socks, or Washable Filter Elements with a Centrifuge you can eliminate the need for disposable filter elements

Particles - Any centrifuge will remove heavier-than-oil particles, but it will find it more difficult to seperate any particles if the main body of oil is heavily contaminated with material of the same Specific Gravity, in this case it would help if the oil is filtered / settled out to a better standard before pumping into the Centrifuge. The cleaner the main body of oil is, or gets, the faster the rate of separation will be, the progressive cleaning action of the Centrifuge will mean that the speed of cleaning will increase as the oil gets cleaner

Liquids - Any centrifuge will remove heavier-than-oil liquids by the same means as it removes particles, but it will not remove "miscible" liquids, for example liquids that have the same "Specific Gravity" as the oil, or contaminants that are bonded to the oil molecules chemically. It is worth noting particularly with liquids that the maximum capacity of the centrifuge rotor cap (where dirt is held) is approximately 295 Grams, if you pump a lot of water, glycerol, or animal fat through the Centrifuge then it will become full very quickly and this will prevent further separation of contaminants, and additional contaminants will be forced straight through the Centrifuge

Number Of Passes - An OB Series Centrifuge is not designed to purify oil in a single pass, unless the oil is very clean. The speed at which the Centrifuge separates contaminants from oil is determined by the cleanliness of the main body of oil and the RPM (not the RPM alone). The Centrifuge Rotor is driven by oil squirting out from two small jets around the circumference of the rotor base, creating a propulsional force, without the jets the rotor will not spin, so to spin at all it needs to pass oil at a rate of about 3 lpm... if your oil is too contaminated then most contamination will go straight through the Centrifuge with the oil to provide the propulsion, and only a small amount of contamination will be separated in the initial pass/es, if your Centrifuge fails to remove anything after repeated passes then your oil may need to be strained to a better standard beforehand

Perseverance - OB Series Centrifuges take a bit of getting used to, many people expect too-much-too-soon and get frustrated without investigating their problems properly. Most problems are experienced by those who purify waste vegetable oil, and are mostly caused by excessive animal-fat in the oil (this is white in colour at room temperature) Animal Fat makes the oil cloudy and, being almost the same S.G. as the oil, makes it extremely difficult to separate. We recommend passing a small amount of oil through an ion-exchange or cellulose media to determine if any cloudiness is caused by animal fat

For information on how to use a Centrifuge and how we use them ourselves, please see our listing for OB Series, Complete Kits

Working Diagram Shown Below:

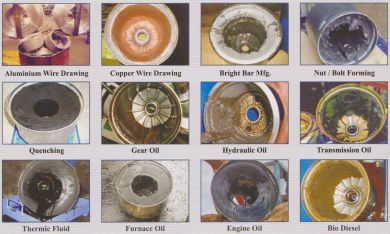

Various Sludge Deposits Shown Below:

Centrifuge Specification| Centrifuge Type | OB-020 | OB-025 | OB-030 | OB-050 | OB-100 | OB-200 | OB-400 | OB-600 |

| Height | 150 mm | 177 mm | 157 mm | 189 mm | 259 mm | 343 mm | 405 mm | 457 mm |

| Height Required for Cap Removal | 230 mm | | | 250 mm | 380 mm | 510 mm | 610 mm | 650 mm |

| Diameter (Approximate) | 103 mm | 103 mm | 109 mm | 140 mm | 185 mm | 230 mm | 290 mm | 338 mm |

| Drain Port Diameter | 40 mm | 40 mm | 40 mm | Complex | 60 mm | 90 mm | 110 mm | 110 mm |

| Mounting Bolt Spacing (4 Bolts) | 45 mm x 45 mm | 45 mm x 45 mm | 50 mm x 50 mm | 76 mm x 54 mm | 70 mm x 80 mm | 126 mm x 126 mm | 126 mm x 126 mm | 126 mm x 126 mm |

| Viewing Window | No | No | No | No | No | Yes | Yes | Yes |

| Weight (Empty) | 1.25 kg | 1.30 kg | 1.4 kg | 2.5 kg | 4.5 kg | 9.5 kg | 23 Kg | 23 kg |

| Max Particle Tolerance | 250 Micron | 250 Micron | 250 Micron | 250 Micron | 250 Micron | 250 Micron | 250 Micron | 250 Micron |

| Max Contaminate Storage | 200 CC | 250 CC | 300 CC | 500 CC | 1000 CC | 2000 CC | 4500 CC | 6000 CC |

| Nozzle Area | | | | | | | | |

| Minimum Pressure | 2 Bar | 2 Bar | 2 Bar | 2 Bar | 3 Bar | 3 Bar | 3 Bar | 3 Bar |

| Max Pressure | 7 Bar | 7 Bar | 7 Bar | 7 Bar | 7 Bar | 7 Bar | 7 Bar | 7 Bar |

| Max Flow Rate | 210 LPH | 210 LPH | 300 LPH | 540 LPH | 600 LPH | 1500 LPH | 3120 LPH | 4500 LPH |

| Inlet Port (All Female) | M12x1.5 | M12x1.5 | 3/8" BSP | M16x1.5 | 3/8" BSP | 1/2" BSP | 3/4" BSP | 3/4" BSP |

| Outlet Port (On Bracket) | 1" BSP | 1" BSP | 1" BSP | 2x 1" BSP | No Bracket | No Bracket | No Bracket | No Bracket |

| Max Temp (Celcius) | 90 | 90 | 90 | 90 | 90 | 90 | 90 | 90 |

| RPM @ 2 Bar | 3500 | 3500 | 4000 | 3500 | 0 | 0 | 0 | 0 |

| RPM @ 3 Bar | 5000 | 5000 | 5000 | 5000 | 3500 | 2500 | 2700 | 2700 |

| RPM @ 4 Bar | 6200 | 6200 | 5800 | 6200 | 4000 | 3400 | 3300 | 3200 |

| RPM @ 5 Bar | 7200 | 7200 | 6500 | 7200 | 4600 | 4000 | 3700 | 3500 |

| RPM @ 6 Bar | 8100 | 8100 | 7200 | 8100 | 5000 | 4500 | 4200 | 3700 |

| RPM @ 7 Bar | 9000 | 9000 | 9000 | 8500 | 5100 | 4750 | 4500 | 3900 |

| Max G Force at Rotor Wall | 3395 G | 3395 G | 3040 G | 3634 G | 1672 G | 2017 G | 2207 G | 2125 G |

See the Oilybits OB-020 Centrifuge on Blue Peter! Click link below;

Read Lindsay Porters 4 Page Article on the OB-020 in the November 2009 Issue of Land Rover Monthly:

Optional Extras:

Sump Mounting Bracket -The Oilybits Centrifuges can also be used on vehicles, to continually purify engine oil by using pressure from the vehicles oil pump bypass. This is done as standard by many American truck manufacturers, but providing your oil pump has a bypass which operates at an appropriate pressure then you can fit the Centrifuges in retrospect. To do this a bracket is available which bolts through the side of a sump (sump removal required to facilitate), this is pictured below and the bracket will fit models OB-020 and OB-025

OB-050 Bracket - OB-050-INVERT Bracket is also available as an accessory for those who purchased from us previously when the bracket was not available

Tariff Code| Description | Code |

| Centrifuge for Liquids | 8421197000 |

Download Centrifugal Filtration - Help Sheet PDF

Download Centrifugal Filtration - Help Sheet PDF

Download Oilybits OB Series Centrifuge - Service Instructions PDF

Download Oilybits OB Series Centrifuge - Service Instructions PDF