Oilybits Centrifugal Oil Cleaning System (Centrifuge on Trolly), 540 to 9000 Litres Per Hour

A fully automatic oil cleaning system, with 500 to 4000 litre hourly fluid capacity. The system is designed to be wheeled to the holding tank of the machine in question, the suction & delivery hoses placed into the tank, and the machine left to run for the desired time. The efficiency of the machine varies dependent on oil viscosity (reduced by temperature), and the type and level of contamination. If the oil temperature is 40c and the type of contamination very heavy in S.G., this will seperate faster than with the opposite characteristics, for example.

The centrifugal filter uses pressurised oil as a wet seal to prevent wear, and turns the incoming liquid flow into a fine jet which propels the rotor at speeds of up to 9100 RPM, creating centrifugal forces of 4166 times gravity. At this point all heavier-than-oil particles such as soot, dirt, swarf and water, are forced to the outside wall of the rotor, where they mass into a solid, or near solid layer, cleaner oil then flows outward. Multiple passes (up to 3) may be required to gain the highest purity, as the centrifuge uses the incoming oil as a wet seal, and therefore passes some dirty oil throughout its operation

By increasing G-Force, you are doubling the relative weight of an object by 100% per 1G, at 0G an object weighs true upon the surface of the earth, at 1 G an object weighs twice its true weight, so, for example at 4000 G, a particle of dirt which might weight 0.1 gram will weigh 400 grams, and because of this, it will settle through a body of liquid much faster than it would if it were its original weight

The centrifuge will require emptying of contaminants periodically, although regularity will depend upon how contaminated your oil is, the cleaner your oil is beforehand, the longer the centrifuge will operate before cleaning is required. The centrifuge is fully user-serviceable

For cleaning of lubrication oil that has been used in a combustion engine, please note that whilst the centrifuge will remove all heavier-than-oil particles, it will not reverse changes that have occurred to the oil at a molecular level - for example the black colour of used engine oil is not only caused by carbon deposits such as soot (which will be removed) but by a change in the molecular structure of the oil caused by the combustion of hydrocarbons within it, this produces black liquids such as asphaltine, and this colouring cannot be removed by using a centrifuge or any other means of fitration.

Standard Features:

- On/Off Switch

- MCB

- Over-Load Relay & Trip Indicator

- Hour Meter

- Over-Flow Indication

- Service Indication Time & Warning Buzzer/Lamp

- Auto Switch Off Facility (after required number of hours)

- 5m Cable

- Suction & Delivery Hoses

- Wheels & Anti-Vibration Mounts

- Pressure Gauge & Control Valve

- Primary Filter

Available with gravity output, or pumped output.

- No filter elements to replace - primary filter can be cleaned

- Improves product finish

- Reduces oil consumption

- Increases oil change interval

- Reduces machine downtime

- Reduces pollution and environmental impact

- Reduces storage and disposal cost of waste oil

- Cost savings on cutting tools, machine tools and replacement parts, filters, and oil

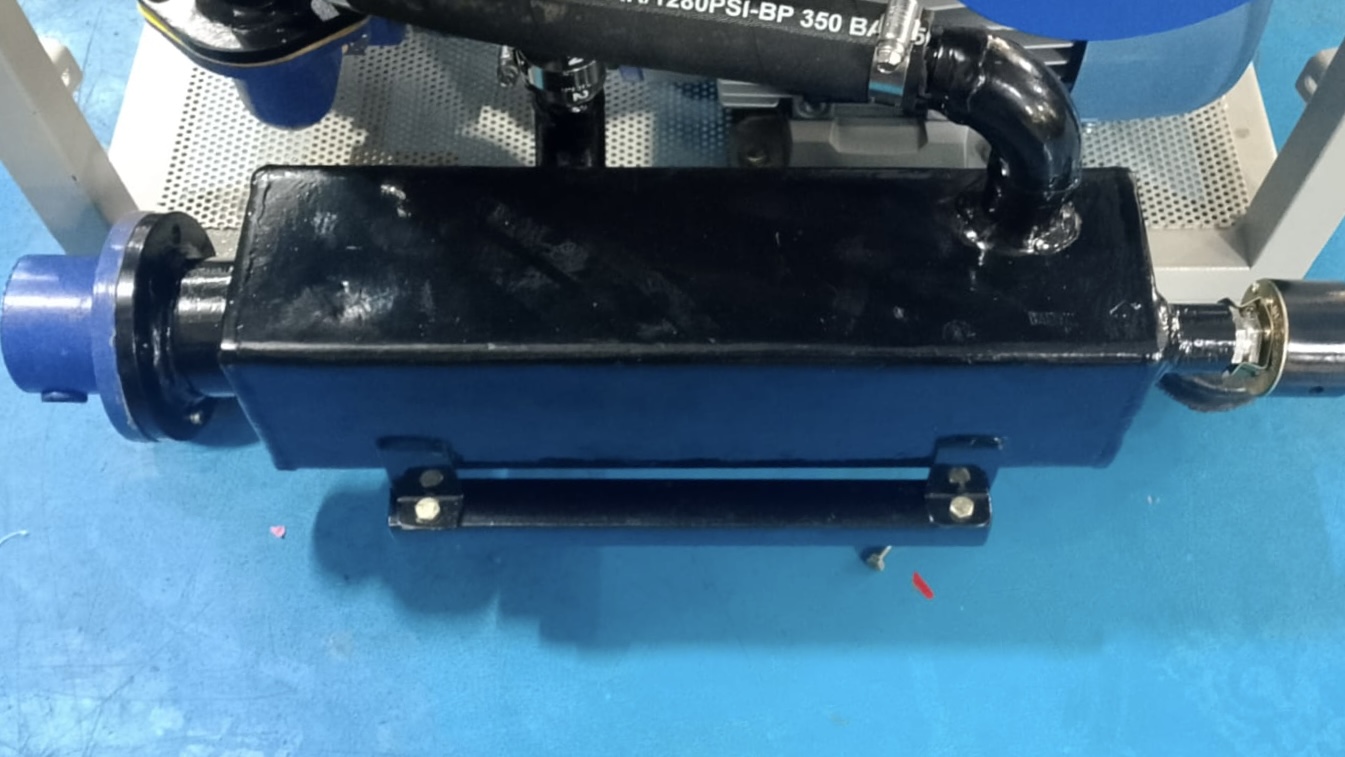

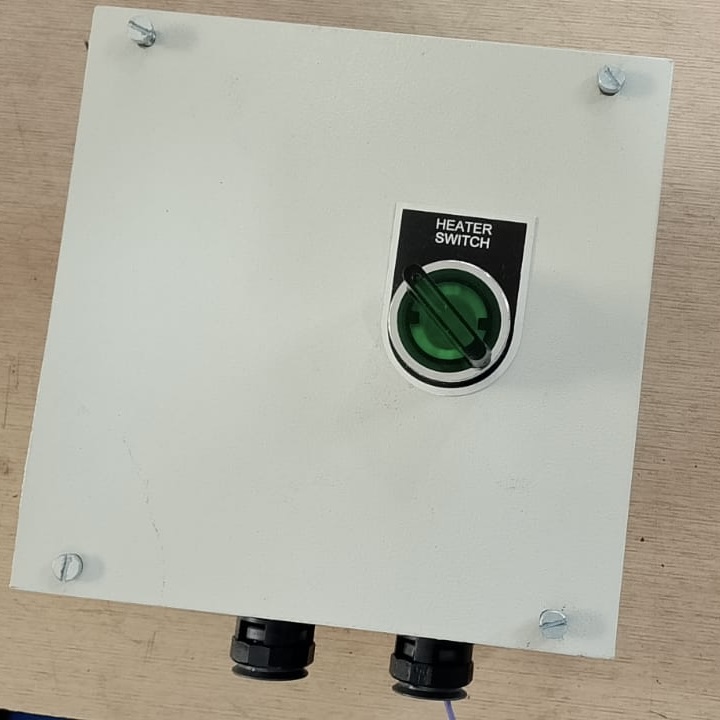

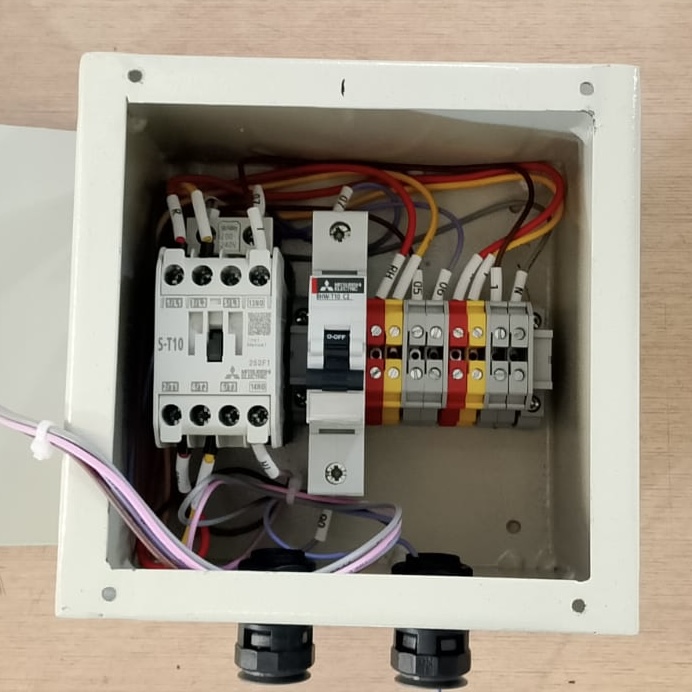

An optional Thermostatic Pre-Heater with independent control panel is also available, this will incease the cleaning efficiency by thinning the oil, breaking emulsions, causing the rotor to rotate faster, and any dirt and water to be ejected from the oil more easily.

Applications:

- Wire Drawing

- Cold Forming

- Fastener Manufacturing

- Heat Treatment

- Bright Bar Manufacturing

- Thread Rolling

- Super Finishing

- Honing

- Grinding

- Gear Boxes

- Cement Mills

- Coal Mills

- Crushers

- Transmissions

- Marine Engines

- Port Equipment

- Mining Equipment

- Diesel Generator Sets

Fluid Compatiblity

- Cutting Oil

- EDM Oil

- Spindle Oil

- Hydraulic Oil

- Gear Oil

- Turbine Oil

- Engine Oil

- Furnace Oil

- Thermic Fluid

- Transmission Oil

- Compressor Oil

- Biodiesel / WVO

- Anti-Rust Oil

- Stamping Oil

- Honing Oil

- Quenching Oil

- Water Emulsions

- Test Bed Oil

AVAILABLE IN VARIOUS VOLTAGES, AND WITH A CHOICE OF PAINT COLOURS (STANDARD=BLUE), EMAIL US FOR PRICE AND AVAILABILITY

Options - Gravity Oil Output| Model | OCS/m-500 | OCS/m-750 | OCS/m-1500 | OCS-4000 | OCS-8000 |

| Featuring Centrifuge Model | OB-050 | OB-100 | OB-200 | OB-600 | 2x OB-600 |

| Maximum Flow Rate | 540 LPH | 600 LPH | 1500 LPH | 4500 LPH | 9000 LPH |

| Voltage | 400v50Hz3Ph (OCSm 220v50Hz1Ph) | 400v50Hz3Ph (OCSm 220v50Hz1Ph) | 400v50Hz3Ph (OCSm 220v50Hz1Ph) | 400v50Hz3Ph | 400v50Hz3Ph |

| Dirt Capacity | 500 cc | 1000 cc | 2000 cc | 6000 cc | 12000 cc |

| Power | 1 HP | TBC HP | TBC HP | TBC HP | TBC HP |

| Delivery Pump | Not Present | Not Present | Not Present | Not Present | Not Present |

| Weight | TBC Kg | TBC Kg | TBC Kg | TBC Kg | TBC Kg |

| Dimensions, L * W * H | 24 * 16 * 35 Inches | 24 * 16 * 35 Inches | 24 * 18 * 39 Inches | 30 * 22 * 46 Inches | 40 * 32 * 48 Inches |

Options - Pumped Oil Output| Model | OCS/m-500P | OCS/m-1000-P | OCS/m-1500-P | OCS-4000-P | OCS-8000-P |

| Featuring Centrifuge Model | OB-050 | OB-100 | OB-200 | OB-600 | 2x OB-600 |

| Maximum Flow Rate | 540 LPH | 600 LPH | 1500 LPH | 4500 LPH | 9000 LPH |

| Voltage | 400v50Hz3Ph (OCSm 220v50Hz1Ph) | 400v50Hz3Ph (OCSm 220v50Hz1Ph) | 400v50Hz3Ph (OCSm 220v50Hz1Ph) | 400v50Hz3Ph | 400v50Hz3Ph |

| Dirt Capacity | 500 cc | 1000 cc | 2000 cc | 6000 cc | 12000 cc |

| Power | 1 HP | TBC HP | TBC HP | TBC HP | TBC HP |

| Delivery Pump | TBC HP | TBC LPH | TBC LPH | TBC LPH | TBC LPH |

| Weight | 150 Kg | TBC Kg | TBC Kg | TBC Kg | TBC Kg |

| Dimensions, L * W * H | 36 * 33 * 47 Inches | 36 * 33 * 47 Inches | 36 * 33 * 47 Inches | TBC | TBC |

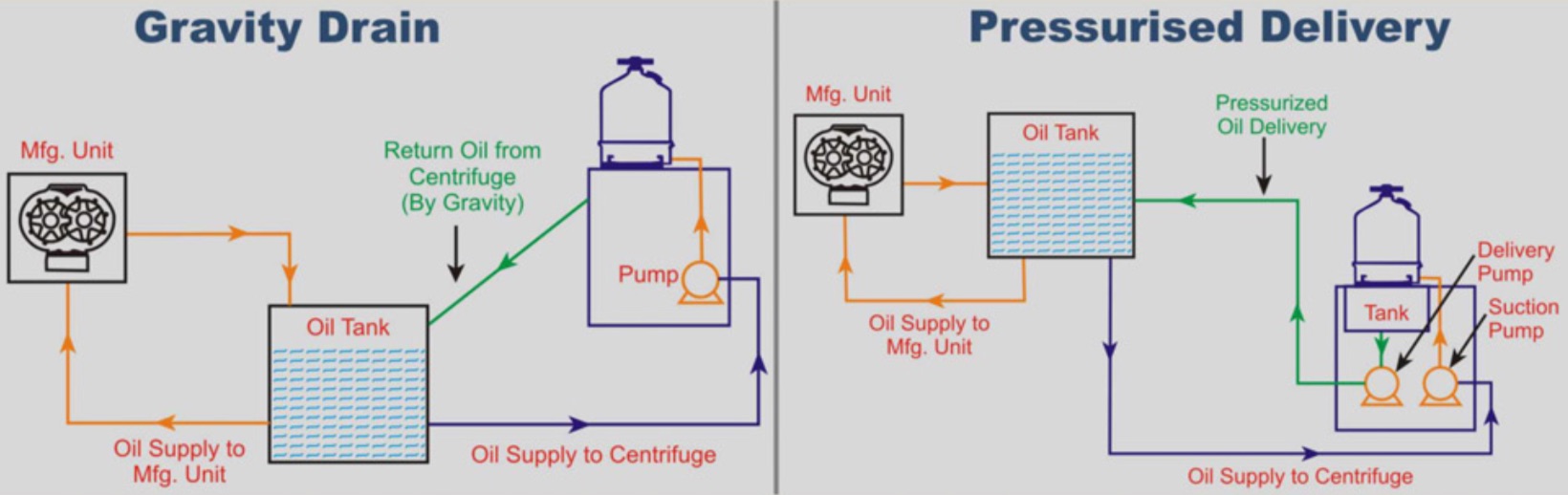

Shown below - Installation Schematic:

Shown Below - Different Types of Sludge:

Download Centrifugal Filtration - Help Sheet PDF

Download Centrifugal Filtration - Help Sheet PDF

Download Oilybits OB Series Centrifuge - Service Instructions PDF

Download Oilybits OB Series Centrifuge - Service Instructions PDF

Download Oilybits OB-050-INVERT Centrifuge - Service Instructions PDF

Download Oilybits OB-050-INVERT Centrifuge - Service Instructions PDF